Oil Deodorizing: Most heat of bleached oil is recovered by heat exchangers, the bleached oil is heated to the process temperature by mineral oil or high pressure steam and then the oil enters into the combined deodorizer, the oil deodorzing is a combined type: the upper is packing structure, which is used to remove odor components like FFA, the lower is plate type used for heat bleaching and making product quality more consistent. Oil coming from the oil deodorzing is cooled and stored after series of heat exchange, volatile like FFA is collected and stored as by products.

Physical Refining

Oil Deodorzing

Combined Deodorizing--Oil Mill Plant

Combined deodorizing is the latest technology, which improves oil flexibility significantly.

Detailed deodorizing process is: Most heat of bleached oil is recovered by Heat Exchangers. The bleached oil is heated to the process temperature by mineral oil or high pressure steam and then the oil enters into the Combined Deodorizer. The Deodorizer is a combined type: The upper is packing structure, which is used to remove odor components like FFA; the lower is a plate type used for heat bleaching and making product quality more consistent. Oil coming from the Deodorizer is cooled and stored after series of heat exchanger. Volatile like FFA is collected and stored as by-products. The technology has following features:

1. Advanced technology makes it widely used oil plants;

2. Optimized heat exchange system makes the energy consumption less and the oil quality is good;

3. With Strong de-acidifying power, the Combined Deodorizer can reduce the acid value of oil to be deodorized from 8mg KOH/g to 0.2mg KOH/g in short time;

4. Physical refining can be realized by cooperating with the oilseed pretreatment technology and extraction technology.

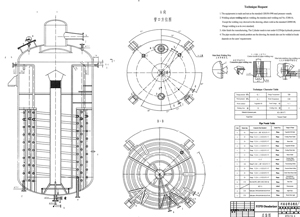

Standard Deodorization Structure

Deodoriztion Pot is a vertical cylinder, there are Elliptical seal heads at the top and bottom, the top cap has Air Bag to keep certain boiling space , the light and the sight glass, at 180°position, on the top of the pot, there is foam board to escape the loss from splashing;

Inside the pot, the coiling pipes is for oil heating and cooling;

At the bottom of the pot, it is equiped with the Direct Steam Ejecting Pipe,

In the Centre of the pot, there is also with Oil Cirlucation Device, the Oil Circulation Device includes:

Orderliness Jet Nozzle, Centre Circulation Pipe and Oil Keeping Cover

Operation:

Open the Steam Valve and Cooling Water Valve of Steam Ejecting Pump, Vacuum the deodorization pot, When the Vacuum reach at 13Kpa, open the oil entering valve, the Decolorized oil will be sucked into the deodorization pot by the vacuum.

Open Heat Condition Oil or Heating Steam valves. (165℃, if for desolventizing, only heating to 140℃ is ok)When Oil gets to 100℃, open the Direct Steam to make the oil rolling / boiling in pot.

The time for ejecting Direct Steam is: 2~4 hours. During the whole deodorization. The vacuum must keep the residual pressure at 0.13~0.8KPa, Direct steam must keep the ejecting quantity at 5%~15% of the oil weight. Shut the Heat conduction oil or Heating Steam valve, 30minutes before stopping deodorization. When finish the deodorization, Close the Direct Steam,, then open the cooling water valve, when the oil cools to under 70℃, close the Steam ejecting pump, break the vacuum,, the deoderized oil can be pump out.

AGICO is the main Chinese oil expellers manufacturer, who have specialised in the design and manufacture of oil milling plants. we offer oil deodorizing.High quality,best service.